NEW HARDWOOD SAWMILL IN BAMBIDIE

At its production site in Bambidie, Gabon, Precious Woods has commenced operations at a new sawmill to expand its processing capacities. This became necessary given that a new forest area will be managed starting in 2020, characterised by a very high density of azobé, a very hard and heavy tree species. With this expansion, Precious Woods is investing in further processing and value creation on site, enabling it to increase its export volume in the longer term.

Regular rotation into a new zone

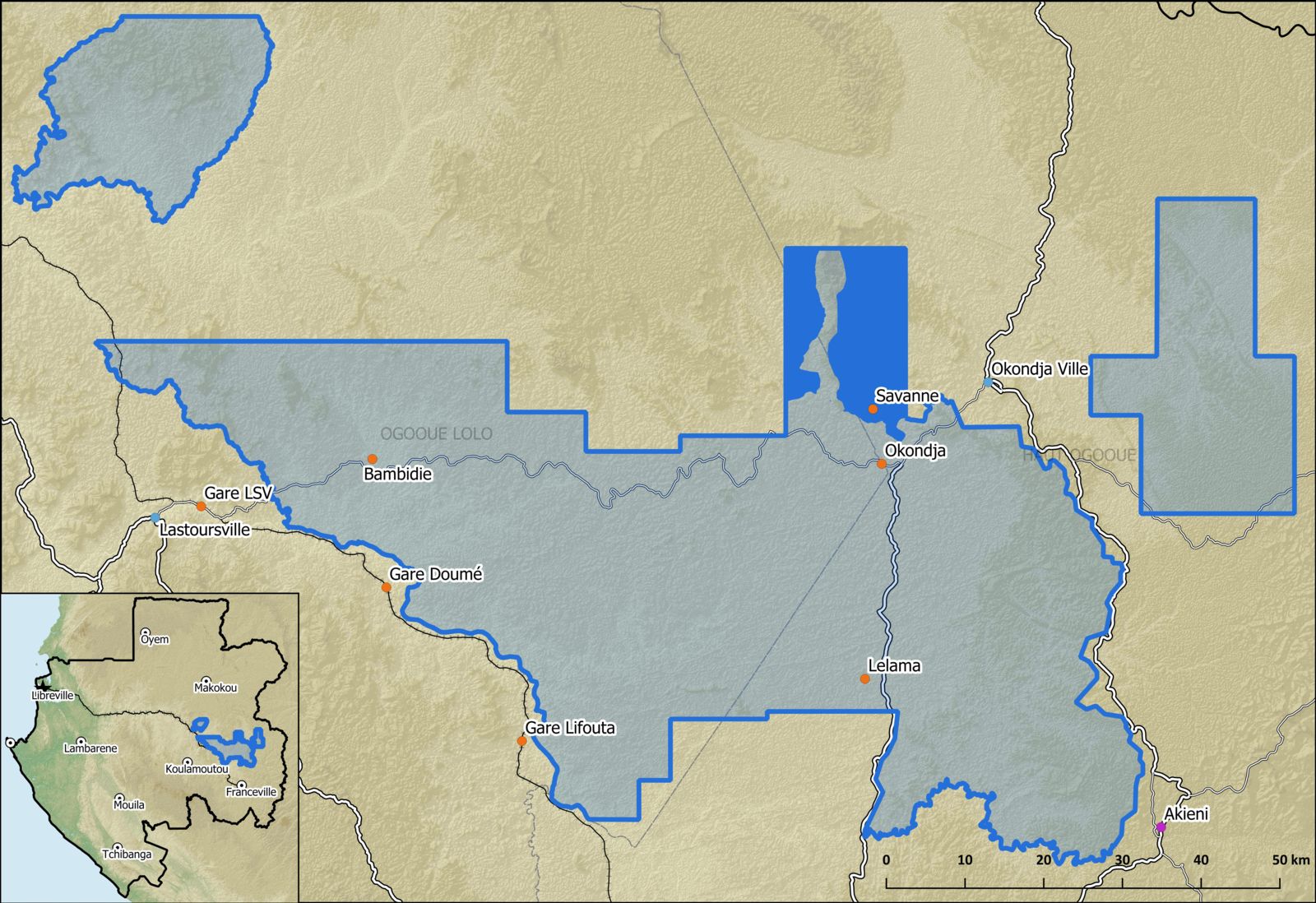

As part of its sustainable forest management, Precious Woods works with a rotation cycle of 25 years. For this purpose, the forest concession in Gabon is divided into different management regions (UFA – Unité Forestière d'Aménagement, UFG – Unité Forestière de Gestion) which are divided into blocks of 5 years each. Starting in 2020 for a period of five years, Precious Woods will manage a zone near the city of Okondja, which has a very high density of azobé (Lophira alata, also known as ekki and bongossi).

Figure 1: Location of the forest area to be cultivated from 2020 to 2024 (dark blue)

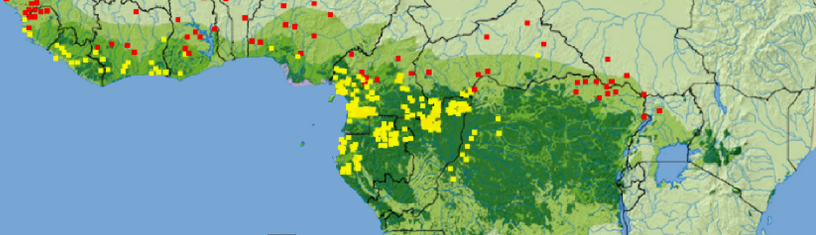

Azobé is a tree species widespread in Central Africa. It can grow up to 60 metres high and 1.5 metres thick and is distinguished by beautiful cylindrical trunks. Due to its biological properties, it is not common throughout all of Precious Woods' concession, but it does form very dense populations regionally. As part of sustainable management, an inventory of the new forest area was established and the usable volume was determined together with the government authorities. In the interests of sustainability and to a natural regeneration, only individual trees with a diameter of more than 80 centimetres are used.

Figure 2: Distribution of azobé in Central Africa (yellow dots, Biwolé et al 2012)

Partnership and construction

Despite the selective use of individual trees, the volume of trees that can be used sustainably will increase from 2020. Together with Azobé, other heavy hardwood species will also be harvested. In light of this, Precious Woods commissioned a study, as a result of which it decided to expand its processing capacities by building a new sawmill.

Figure 3: Production site of Wijma in Kampen, Netherlands

To implement this project, Precious Woods entered into a partnership with the Dutch firm Koninklijke Houthandel G. Wijma & Zonen B.V., which specialises in the processing and trading of azobé and has been active in timber processing for over 120 years. With more than 60 years of experience in sustainable forestry and the processing of tropical woods in Africa, Wijma is an ideal partner.

One of the main reasons why Precious Woods is the partner of choice for Wijma, is its reputation regarding sustainable forest management practices and the fact, that its operations are double certified (FSC and PEFC).

Wijma has advised Precious Woods on the planning and construction of the new sawmill for processing azobé and other hardwood species. The azobé sawn timber produced will be further processed and marketed by Wijma for construction projects in Europe.

Sawmill

Figure 4: Left the new azobé sawmill, next to it the existing sawmill for processing various types of sawn wood ("bois divers")

The new sawmill was built directly next to an existing sawmill (for various types of sawn wood, or "bois divers") in order to make the best possible use of the existing infrastructure. The sawmill employs 80 people working in two shifts on four band saws, two edgers, and a recovery line for processing waste wood. 41 000 cubic metres of logs can be processed into 17 000 cubic metres of sawn timber each year.

With the launch of the new sawmill, about 165 000 cubic metres of logs can now be processed per year in Bambidie.

Figure 5: The azobé sawmill during construction and installation

Figure 6: Band saw in operation at the azobé sawmill

Figure 7: Band and head saws in operation at the azobé sawmill

Products and use

Due to its technical properties, azobé is used primarily for outdoor and water applications. The wood is very hard and durable and can therefore also be used for technically demanding construction projects. One cubic metre of azobé weighs about 1 300 kilograms, which makes it heavier than water and one of the heaviest known tree species. Because of its good resistance, azobé is almost the only tree species that can be used untreated for constructions in water.

Figure 8: Azobé wood packages ready for export to the Netherlands

This property means, for instance, that bridges, lock gates, docks, and dam reinforcements are often made of azobé. This makes azobé a sustainable and renewable alternative to other building materials such as steel and concrete.

Wijma specialises in the processing of azobé and in buildings with tropical woods and realises a large number of construction projects every year. As part of the new cooperation arrangement, Precious Woods is becoming Wijma's most important supplier, thus securing the sale of its production. The sawn timber from our concession will be used for high-quality, long-term applications, supporting Precious Woods' sustainable operations.

Pictures of projects realized by Wijma Kampen with Azobé:

Figure 9: Bride over a highway

Figure 10: Bicycle bridge

Figure 11: Bridge for pedestrians

Figure 12: Roof construction in combination with solar panels

Figure 13: Lockgate

.jpg)

Figure 14: Dike reinforcement

Figure 15: Harbour quay

.jpg)

Figure 16: Lane separators